Achieves Approved Document E performance standards for Floor Type 1.

Green Label Plus accredited for indoor air quality and low VOC emissions.

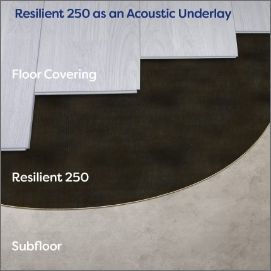

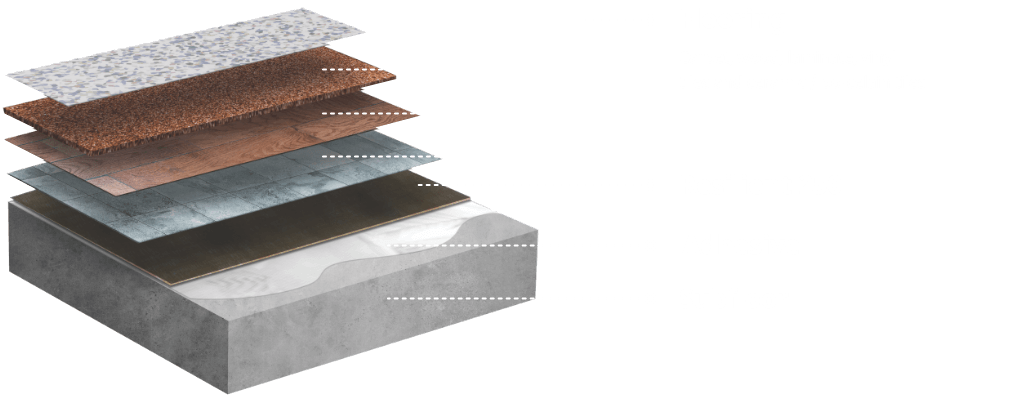

Resilient 250 is a high performing acoustic resilient layer that has been designed to significantly reduce impact sound. It can be used as used as a Soft Floor Covering or as an Acoustic Underlayment.

Why Resilient 250?

Resilient 250 is quick and easy to work with and can be used with a wide range of floor coverings, providing exceptional acoustic performance to the finished installation. Being manufactured from sponge rubber, it provides long-lasting durability and strong resistance to foot traffic, following installation of the floor covering. Resilient 250 exceeds the requirements for a Soft Floor Covering in Approved Document E (England & Wales), Technical Booklet G (Northern Ireland) and Section 5 of the Building Standards in Scotland.

Achieves Approved Document E performance standards for Floor Type 1.

Green Label Plus accredited for indoor air quality and low VOC emissions.

(no floor coverings and no ceiling below)

(with floor covering and no ceiling below)

| ΔLw | IIC | ΔIIC | |

|---|---|---|---|

| Luxury Vinyl Tiles (2.5mm) | 20 | 54 | 24 |

| Luxury Vinyl Tiles (4.5mm) | 20 | 54 | 24 |

| Luxury Vinyl Tiles (5mm) | 21 | 55 | 25 |

| Sheet Vinyl (2mm) | 18 | 51 | 22 |

| Linoleum (2.5mm) | 18 | 52 | 22 |

| Laminate (8mm) | 18 | 52 | 22 |

| Engineered Wood (14mm) | 17 | 51 | 21 |

| Carpet Tile (Bitumen Backed) | 30 | 64 | 30 |

| Ceramic Tile (9mm) | 17 | 50 | 21 |

* Tested on a 140mm / 5½” thick concrete floor.

(with floor covering and suspended ceiling)

| HIIC | IIC | STC | |

|---|---|---|---|

| Luxury Vinyl Tiles (4.77mm) | 91 | 73 | 65 |

| Luxury Vinyl Tiles (5mm) | 92 | 72 | 64 |

†Tested with a floor-ceiling assembly - 152mm / 6” thick concrete slab.

Resilient 250 is widely used in developments where high levels of acoustic performance are required. It is therefore used in applications requiring compliance with Approved Document E – Floor Type 1 (concrete base with ceiling and soft floor covering). It must be bonded to the subfloor to comply with Approved Document E.

As an acoustic underlay, Resilient 250 can be used below the following types of floor coverings.

Full technical specifications can be downloaded below.

For further information fill out our enquiry form or email sonixx@interfloor.com

Sonixx® specialist acoustic underlays significantly reduce sound transmission and have the durability and resilience to remain in situ for decades.